Tel.: +86 13358378970

E-mail: sales6@saulplc.com

Tel.: +86 13358378970

E-mail: sales6@saulplc.com

Jul. 14, 2023

wo years later, SEMICON China 2023, a grand event of semiconductor industry, was grandly restarted in Shanghai New International Expo Center from June 29 to July 1. The exhibition gathered equipment, material and automation manufacturers in the semiconductor manufacturing field, and demonstrated the cutting-edge technologies and achievements of the Semiconductor industry chain.

As an automation expert who has worked hard in the field of automation for 90 years, Omron has continued to develop in the semiconductor industry and accumulated rich industry experience. To address the semiconductor industry issues, we propose a new and evolving SEMI/FPD industry solution based on core technologies such as AI, robotics, and digitization, which meets market demands. We will share it with global audiences at this SEMICON!

For three consecutive days, the Omron booth was crowded, and the high temperature and rainstorm could not stop the enthusiasm of the "semiconductor people". New and old friends gathered at the booth to have a talk, and jointly tasted Omron SEMI/FPD industry solutions. They collided with new sparks in the exchange and looked forward to the win-win future of cooperation.

Omron revolves around the evolving i-Automation! The three directions of conceptual new manufacturing, namely "beyond human automation", "highly collaborative between humans", and "digital engineering innovation", showcase cutting-edge solutions and innovative applications in the SEMICON/FPD manufacturing industry.

*In terms of "beyond human automation", we use high-speed and high-precision control application technology as the foundation, and use IoT, AI, and robot technology to complete all types of operations and businesses involved in the production process by machines, making the entire process automation a reality.

The quality of temperature control in heat treatment processes can have a significant impact on product quality and yield. Previous control techniques have found it difficult to control the deviation of workpiece temperature during the heating process. Taking the semiconductor industry as an example, there are issues such as unstable yield due to temperature deviation, and the need for complex adjustment processes for multi-point temperature settings.

Omron's self-developed "workpiece temperature uniformity technology (patented)" can reduce the temperature deviation of the workpiece and its vicinity by more than 70% (the company's data), and improve product quality. In addition, the automatic generation technology of temperature feature quantities can accurately adjust the temperature even with tens or more heating points, without the need for manual intervention.

The popularity of smartphones and electric vehicles has led to an increasing demand for electronic components. Laser processing is one of the production processes for electronic components. In traditional methods, platform movement and galvanometer control are sequentially executed, that is, "step-by-step and repetitive" processing is performed. The movement and stopping of repetitive operations reduce production efficiency.

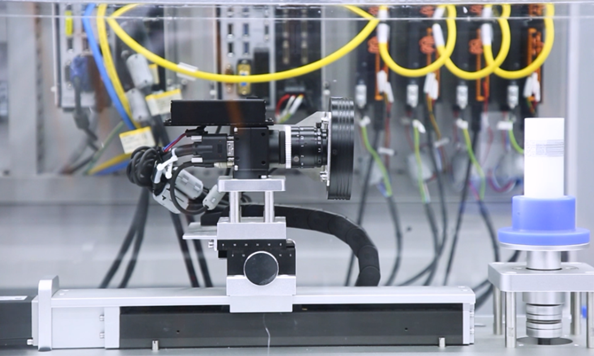

The Omron programmable multi axis motion controller endows the platform with nanometer level positioning accuracy and control performance, which can achieve high-precision measurement, high-precision machining, micro advancement, etc., and help to achieve ultra precision I-shaped motion, with error ≤ 0.2 μ M. For example, when applied to wafer AOI detection, the platform needs to achieve key requirements such as high dynamic and fast point positioning, minimum speed fluctuation under uniform speed, and Z-axis high dynamic tracking and focusing under high-power microscope. Through the ultra-high speed response of Omron programmable multi axis motion controller, PWM control and Omron's self-developed high tracking core technology, the platform provides more accurate detection effects, enabling wafer laser steganography and AOI wafer detection.

In terms of appearance inspection, although the previous pause inspection had high positional accuracy, the shooting speed was slow; The previous continuous shooting speed has been improved, but the positional accuracy is too low.

Omron's non-stop high-speed inspection technology effectively solves the problem of inspection pause, improves productivity, and reduces the time of portrait inspection by 70%. On the other hand, this technology can accurately capture and recognize high-speed rotating QR codes while ensuring shooting speed.

*"High human-computer cooperation" aims to give consideration to the sense of achievement and work efficiency of employees, flexibly use Omron's highly integrated sensing technology, robots and safety equipment for human actions, and achieve seamless human-computer connection that was difficult to achieve before.

Mobile Manipulation Robot Application (MoMA) is a comprehensive solution that combines the mobility agility of LD and the operability of arm type collaborative robots by equipping them with collaborative robots. In addition to using LD to automatically move items, arm type collaborative robots can also be used to automatically load and unload items. MoMA can be applied to the handling of crystal boxes, changing the manual handling method, saving manpower, accelerating efficiency, and promoting the development of manufacturing sites towards more intelligent and flexible.

Navigation

Add.: 9D, 9th Floor, Huguang Building, Hubin West Road, Siming District, Xiamen City, Fujian Province, China

Tel.: +86 13358378970

Mob.: +86 13358378970

E-mail: sales6@saulplc.com

WhatsApp: +86 13358378970

Wechat: +86 13358378970